The term “lightweight concrete” is defined as lower-density concrete which also means normal weight. The ACI committee 213 explains that lightweight concrete is made up of rocks which are also known as coarse aggregates and regular sand called aggregates. However, some of the time lightweight sand can also be included. The practical challenge is the weight of the concrete, although it is a very durable material.

But, this challenge exists even when modern technologies are invented. Large cranes and trucks have to lift heavy structural weights and loads during transportation. So, by using lighter concrete or lightweight concrete, the issue has been minimized. If you are planning to construct a building, you must know exactly how much concrete is going to cost you! For that, you can seek help from professional concrete estimators. These experts provide a straight roadmap to accurate cost evaluations. Without wasting any further time, let’s discuss what exactly is lightweight concrete!

DIVE IN TO EXPLORE WHAT IS LIGHTWEIGHT CONCRETE, ITS APPLICATIONS, AND TYPES, AND HOW YOU CAN ENHANCE YOUR CONSTRUCTION PROCESSES WITH THIS COST-EFFECTIVE MATERIAL!

Brief Introduction to Lightweight Concrete

The density of lightweight concrete ranges between 1400-1800 kg/m3 and compressive strength values between 7 and 28 MPa.

More work, it is a mixture that is made with lightweight courses such as shale, clay, or slate. Due to these materials, the concrete is considered to be lower density as compared to the standard ones. The normal density of regular concrete ranges between 140 to 150 lb/ft³. On the other hand, structural lightweight concrete density is between. On the other hand, structural lightweight concrete density is between. 90 to 115 lb/ft³.

This means that lightweight concrete is ideal for building modern structures. However, its usage is increasing day by day to build foundations and as an alternative to standard concrete!

Types of Lightweight Concrete

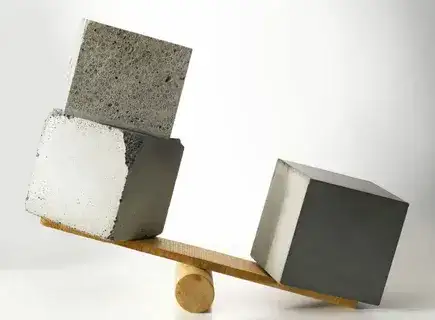

Why Lightweight concrete is so unique? Due to its ability to reduce the weight of the structure while maintaining its strength. But, how it is achieved? By using materials that are less dense than traditional concrete but strong. Let’s discuss different types of lightweight concrete:

1. Lightweight Aggregate Concrete

Lightweight Aggregate Concrete is produced by using some materials. It includes expanded clay, shale, slate, or pumice instead of standard aggregates. All these materials have porous structures which helps in reducing density. Where it is used? For those structures which require less weight!

- The density of lightweight aggregate concrete is about 90 to 115 pounds per cubic foot (PCF).

2. Aerated (Cellular) Concrete

Do you know what is an interesting fact about aerated concrete? It is developed by filling air or gas bubbles into the mixture. This approach produces a cellular structure. Usually, it is achieved by adding aluminum powder to the mix. As a result, the concrete is lightweight, and insulating materials are used in panels for doors and walls.

- The density of aerated concrete varies from 25 to 100 pcf. It depends on how much air is introduced into it.

3. No-Fines Concrete

In no-fines concrete, sand is not used rather large stones are mixed with the cement mixture. Why so? Because it leaves gaps in concrete that make it lighter than usual. Moreover, no-fines concrete is used in those walls and structures that need to be strong and provide good insulation.

- The density of no-fine concrete is lighter than the standard concrete but more than aerated types.

Why Lightweight Concrete is emphasized?

Lightweight concrete is emphasized due to its characteristics and reduced weight. By using air voids and lightweight materials, it has reduced heavy loads of structures.

However, this makes it an ideal choice for structures, bridges, and other applications. Mainly, in those areas where less weight is required. The American Concrete Institute (ACI) emphasizes using lightweight concrete. So, seek ACI certifications to ensure the production and application of lightweight concrete based on standards. It will improve the overall outputs of modern structures.

SO, USE LIGHTWEIGHT CONCRETE FOR YOUR NEW PROJECTS TO SEE A HUGE DIFFERENCE IN THE MONEY SPENT! IN CASE OF ANY BUDGET ADVICE, CONTACT OUR QUALIFIED ESTIMATORS AND GET QUOTES!

Conclusion

In short, investing in lightweight concrete is never a bad choice! It is budget-friendly as compared to normal heavy concrete. Most importantly, the strength is not compromised! Moreover, lower weight means you will need lower transportation. For precise estimates, you can seek help from professional cost-estimating services to handle funds. Not only that, the higher use of spaces in lightweight concrete reduces heat transfer. So, you no longer need to worry about insulation!